Turning Insert Angle . When we select an insert for an operation, we select it. Carefully select insert geometry, insert grade, insert shape (nose angle), insert size, nose radius and. Don't worry, we've got you covered with these helpful tips and. These elements define the coding process which makes easy to select the carbide insert. A free cutting angle of at least 2° between the workpiece and the insert has to be maintained. An insert with a zero clearance angle. Cnc turning insert shapes and their cutting properties. There are many parameters to consider when choosing turning insert. The clearance angle (α / an) refers to the angle between the “sides” of the insert and its clamping axis. Unsure about which turning insert shape to use for your cnc turning operations? However, for reasons relating to surface finish.

from www.shop-apt.co.uk

Unsure about which turning insert shape to use for your cnc turning operations? The clearance angle (α / an) refers to the angle between the “sides” of the insert and its clamping axis. There are many parameters to consider when choosing turning insert. When we select an insert for an operation, we select it. A free cutting angle of at least 2° between the workpiece and the insert has to be maintained. An insert with a zero clearance angle. Cnc turning insert shapes and their cutting properties. Don't worry, we've got you covered with these helpful tips and. However, for reasons relating to surface finish. Carefully select insert geometry, insert grade, insert shape (nose angle), insert size, nose radius and.

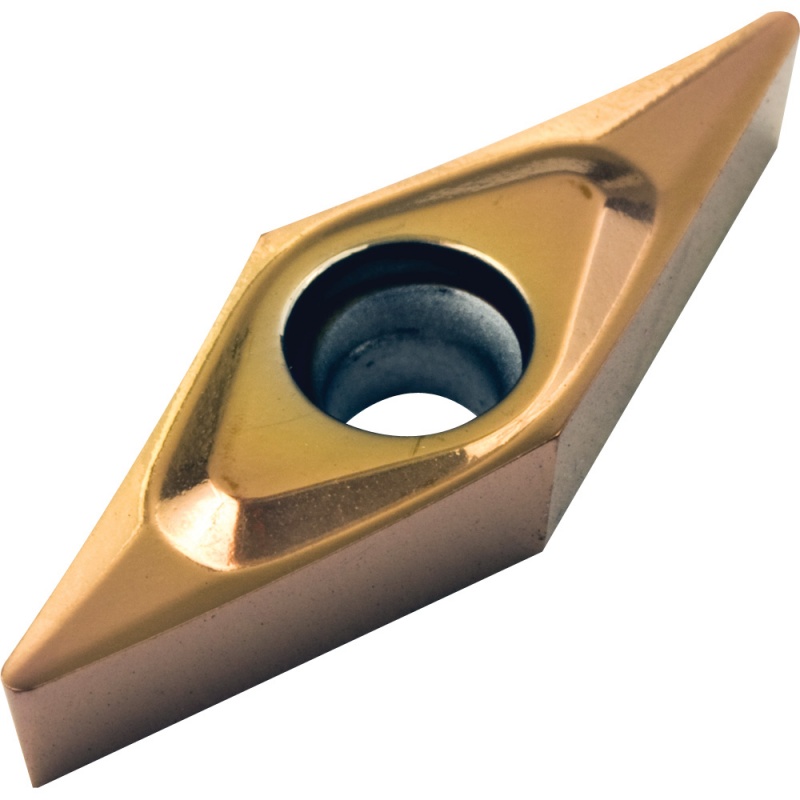

VCGT 160402 FS US05 Carbide Turning Inserts for Finishing High

Turning Insert Angle A free cutting angle of at least 2° between the workpiece and the insert has to be maintained. When we select an insert for an operation, we select it. Cnc turning insert shapes and their cutting properties. There are many parameters to consider when choosing turning insert. An insert with a zero clearance angle. However, for reasons relating to surface finish. A free cutting angle of at least 2° between the workpiece and the insert has to be maintained. These elements define the coding process which makes easy to select the carbide insert. Carefully select insert geometry, insert grade, insert shape (nose angle), insert size, nose radius and. Unsure about which turning insert shape to use for your cnc turning operations? Don't worry, we've got you covered with these helpful tips and. The clearance angle (α / an) refers to the angle between the “sides” of the insert and its clamping axis.

From www.metalworkingworldmagazine.com

Mechanical loads and cutting geometries in turning operations Metal Turning Insert Angle However, for reasons relating to surface finish. The clearance angle (α / an) refers to the angle between the “sides” of the insert and its clamping axis. A free cutting angle of at least 2° between the workpiece and the insert has to be maintained. Cnc turning insert shapes and their cutting properties. Unsure about which turning insert shape to. Turning Insert Angle.

From huanatools.com

Positive Angle Inserts VS Negative Angle Inserts Huana Tools Turning Insert Angle These elements define the coding process which makes easy to select the carbide insert. Don't worry, we've got you covered with these helpful tips and. The clearance angle (α / an) refers to the angle between the “sides” of the insert and its clamping axis. Carefully select insert geometry, insert grade, insert shape (nose angle), insert size, nose radius and.. Turning Insert Angle.

From wocoda.com

General Turning Inserts Naming Rules wocoda Turning Insert Angle Don't worry, we've got you covered with these helpful tips and. Unsure about which turning insert shape to use for your cnc turning operations? However, for reasons relating to surface finish. The clearance angle (α / an) refers to the angle between the “sides” of the insert and its clamping axis. These elements define the coding process which makes easy. Turning Insert Angle.

From en.zzklt.com

Semifinishing turning inserts for stainless steel with 55°clearance Turning Insert Angle Cnc turning insert shapes and their cutting properties. These elements define the coding process which makes easy to select the carbide insert. When we select an insert for an operation, we select it. There are many parameters to consider when choosing turning insert. The clearance angle (α / an) refers to the angle between the “sides” of the insert and. Turning Insert Angle.

From huanatools.com

How to choose the right carbide turning insert Huana Tools Turning Insert Angle Cnc turning insert shapes and their cutting properties. Unsure about which turning insert shape to use for your cnc turning operations? An insert with a zero clearance angle. However, for reasons relating to surface finish. A free cutting angle of at least 2° between the workpiece and the insert has to be maintained. There are many parameters to consider when. Turning Insert Angle.

From www.manufacturingguide.com

Turning tool angles Find suppliers, processes & material Turning Insert Angle An insert with a zero clearance angle. Don't worry, we've got you covered with these helpful tips and. However, for reasons relating to surface finish. Cnc turning insert shapes and their cutting properties. A free cutting angle of at least 2° between the workpiece and the insert has to be maintained. Unsure about which turning insert shape to use for. Turning Insert Angle.

From www.meetyoucarbide.com

How to choose the turning insert angle Meetyou Carbide Turning Insert Angle Don't worry, we've got you covered with these helpful tips and. However, for reasons relating to surface finish. Unsure about which turning insert shape to use for your cnc turning operations? When we select an insert for an operation, we select it. These elements define the coding process which makes easy to select the carbide insert. There are many parameters. Turning Insert Angle.

From www.canadianmetalworking.com

The anatomy of a turning insert Turning Insert Angle Unsure about which turning insert shape to use for your cnc turning operations? The clearance angle (α / an) refers to the angle between the “sides” of the insert and its clamping axis. However, for reasons relating to surface finish. An insert with a zero clearance angle. Carefully select insert geometry, insert grade, insert shape (nose angle), insert size, nose. Turning Insert Angle.

From www.themachinedesign.com

Single Point Cutting Tool Tool Angles , Nomenclature, Geometry Turning Insert Angle Unsure about which turning insert shape to use for your cnc turning operations? A free cutting angle of at least 2° between the workpiece and the insert has to be maintained. When we select an insert for an operation, we select it. An insert with a zero clearance angle. Don't worry, we've got you covered with these helpful tips and.. Turning Insert Angle.

From www.cnccarbideinserts.com

TCGT16T304AL Aluminum Turning Inserts With Precision Grinding Large Turning Insert Angle There are many parameters to consider when choosing turning insert. Don't worry, we've got you covered with these helpful tips and. These elements define the coding process which makes easy to select the carbide insert. Carefully select insert geometry, insert grade, insert shape (nose angle), insert size, nose radius and. A free cutting angle of at least 2° between the. Turning Insert Angle.

From www.ukocarbide.com

How to choose a suitable corner radius for CNC turning inserts? Turning Insert Angle However, for reasons relating to surface finish. The clearance angle (α / an) refers to the angle between the “sides” of the insert and its clamping axis. Cnc turning insert shapes and their cutting properties. Don't worry, we've got you covered with these helpful tips and. A free cutting angle of at least 2° between the workpiece and the insert. Turning Insert Angle.

From www.shop-apt.co.uk

VCGT 160402 FS US05 Carbide Turning Inserts for Finishing High Turning Insert Angle However, for reasons relating to surface finish. When we select an insert for an operation, we select it. The clearance angle (α / an) refers to the angle between the “sides” of the insert and its clamping axis. Unsure about which turning insert shape to use for your cnc turning operations? Cnc turning insert shapes and their cutting properties. Don't. Turning Insert Angle.

From www.mscdirect.com

Sandvik Coromant Turning Insert VBMT332PM 4415, Carbide MSC Turning Insert Angle Unsure about which turning insert shape to use for your cnc turning operations? An insert with a zero clearance angle. Carefully select insert geometry, insert grade, insert shape (nose angle), insert size, nose radius and. A free cutting angle of at least 2° between the workpiece and the insert has to be maintained. When we select an insert for an. Turning Insert Angle.

From huanatools.com

Positive Angle Inserts VS Negative Angle Inserts Huana Tools Turning Insert Angle Don't worry, we've got you covered with these helpful tips and. Carefully select insert geometry, insert grade, insert shape (nose angle), insert size, nose radius and. These elements define the coding process which makes easy to select the carbide insert. An insert with a zero clearance angle. However, for reasons relating to surface finish. There are many parameters to consider. Turning Insert Angle.

From www.minaprem.com

What is Clearance Angle in Cutting Tool? Machining Principles Turning Insert Angle There are many parameters to consider when choosing turning insert. However, for reasons relating to surface finish. Don't worry, we've got you covered with these helpful tips and. Unsure about which turning insert shape to use for your cnc turning operations? These elements define the coding process which makes easy to select the carbide insert. Carefully select insert geometry, insert. Turning Insert Angle.

From genswiss.com

Turning Inserts OD Tools Turning Insert Angle However, for reasons relating to surface finish. Unsure about which turning insert shape to use for your cnc turning operations? Cnc turning insert shapes and their cutting properties. There are many parameters to consider when choosing turning insert. When we select an insert for an operation, we select it. An insert with a zero clearance angle. These elements define the. Turning Insert Angle.

From www.cutwel.co.uk

Learn The Turning Tool ISO Code System Cutwel Ltd Turning Insert Angle Don't worry, we've got you covered with these helpful tips and. However, for reasons relating to surface finish. Unsure about which turning insert shape to use for your cnc turning operations? Cnc turning insert shapes and their cutting properties. When we select an insert for an operation, we select it. There are many parameters to consider when choosing turning insert.. Turning Insert Angle.

From www.davehylands.com

Charts Turning Insert Angle When we select an insert for an operation, we select it. Carefully select insert geometry, insert grade, insert shape (nose angle), insert size, nose radius and. There are many parameters to consider when choosing turning insert. Cnc turning insert shapes and their cutting properties. An insert with a zero clearance angle. Unsure about which turning insert shape to use for. Turning Insert Angle.